Repairing stripped Tx case screws?

Repairing stripped Tx case screws?

Hi,

I've now opened/closed/opened my 9x Tx case that many times that i've stripped the thread out of a couple of the case screws. I was wondering if there was any advice as to the best options for repair? I'm assuming it'll involve some level of glue use to create a new thread, but would appreciate advice as to what sort of glue would best satisfy this requirement and if there are any do/don't advice to go along with it.

Thanks

Peter

I've now opened/closed/opened my 9x Tx case that many times that i've stripped the thread out of a couple of the case screws. I was wondering if there was any advice as to the best options for repair? I'm assuming it'll involve some level of glue use to create a new thread, but would appreciate advice as to what sort of glue would best satisfy this requirement and if there are any do/don't advice to go along with it.

Thanks

Peter

Sv: Repairing stripped Tx case screws?

I had the same problem. To solve it I enlarged all holes slightly and jamed in pieces of hollow nylon pushrod. The thing with nylon is that it is that it does not strip easily.

I then replaced the screws with wood screws. Wood screws have a better taper than the original plastic screws, that are square.

None of my "updated" threads have stripped this far and if they ever do I can pull out the nylon and jam in a new piece.

I then replaced the screws with wood screws. Wood screws have a better taper than the original plastic screws, that are square.

None of my "updated" threads have stripped this far and if they ever do I can pull out the nylon and jam in a new piece.

Re: Repairing stripped Tx case screws?

Some of my screws seemed glued from the factory. It like the initial hole was the wrong diameter or it wasnt tapped properly so they glued it. Now when I put it back in it slightly tightens up that is all.

If you dont have the nylon pushrod he mentioned above you could try part of a toothpick in the existing hole. If that is too big use a short section of solder. For even smaller stripped out holes try several strands of dental floss.

If you dont have the nylon pushrod he mentioned above you could try part of a toothpick in the existing hole. If that is too big use a short section of solder. For even smaller stripped out holes try several strands of dental floss.

Re: Repairing stripped Tx case screws?

I might try some epoxy on the screw. Lightly oil the threads of the screw first, so the epoxy doesn't stick to it. The put a little epoxy in the hole and a little on the threads. Put the screw in the hole and wait until the epoxy dries. You should then have a perfectly threaded hole for the screw.

-Gohst

-Gohst

Re: Repairing stripped Tx case screws?

Or a permanently epoxied together case!

- Rob Thomson

- Site Admin

- Posts: 4543

- Joined: Tue Dec 27, 2011 11:34 am

- Country: United Kingdom

- Location: Albury, Guildford

- Contact:

Re: Sv: Repairing stripped Tx case screws?

dvogonen wrote:I had the same problem. To solve it I enlarged all holes slightly and jamed in pieces of hollow nylon pushrod. The thing with nylon is that it is that it does not strip easily.

I then replaced the screws with wood screws. Wood screws have a better taper than the original plastic screws, that are square.

None of my "updated" threads have stripped this far and if they ever do I can pull out the nylon and jam in a new piece.

This is the best idea..

I have tried the epoxy method with little luck long term.

Rob

Slope Soaring, FPV, and pretty much anything 'high tech'

...........if you think it should be in the wiki.. ask me for wiki access, then go add it!

...........if you think it should be in the wiki.. ask me for wiki access, then go add it!

Re: Repairing stripped Tx case screws?

Hi Guys,

I found with my tx that they stripped out nicely to about 2.3mm, the correct size to tap with M3 screw. As long as you dont tighten down with pounds of force ive been able to open and close my case without stripping.

Les

I found with my tx that they stripped out nicely to about 2.3mm, the correct size to tap with M3 screw. As long as you dont tighten down with pounds of force ive been able to open and close my case without stripping.

Les

Repairing stripped Tx case screws?

Any ideas for a cracked post?

Was thinking to CA some carbon tow around it after a drop of plastiweld then coat with epoxy...

Was thinking to CA some carbon tow around it after a drop of plastiweld then coat with epoxy...

- Rob Thomson

- Site Admin

- Posts: 4543

- Joined: Tue Dec 27, 2011 11:34 am

- Country: United Kingdom

- Location: Albury, Guildford

- Contact:

Repairing stripped Tx case screws?

I would rebuild it with milliput epoxy putty!

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

Slope Soaring, FPV, and pretty much anything 'high tech'

...........if you think it should be in the wiki.. ask me for wiki access, then go add it!

...........if you think it should be in the wiki.. ask me for wiki access, then go add it!

Sv: Repairing stripped Tx case screws?

I would smear a small amount of epoxy in the crack and use several layers of shrink tube to pull the post together. Be very, very careful with the heat though. You do not want to melt the case.

Repairing stripped Tx case screws?

Mine weren't cracked, but we're stripped out. I mixed some polyurethane glue with water, and when it started to foam I poked some down the holes with a toothpick and paper clip. I kept adding more until it began to foam over. I wiped off the excess many times. When the glue was solid I scraped off any extra.

The foamy glue gave the screw something to bite, but wasn't do solid that I would have to re-drill the holes.

Dan

The foamy glue gave the screw something to bite, but wasn't do solid that I would have to re-drill the holes.

Dan

- Westy

- Posts: 248

- Joined: Tue Jan 31, 2012 8:44 pm

- Country: -

- Location: Te Awamutu, Waikato, New Zealand

Re: Repairing stripped Tx case screws?

I would (and have) done this.

WARNING ... This will take some time and patience.....

I have used this method with both metal (using either alloy plastic metal or cast metal plastic) and plastic in automotive and earthmoving equipment when I have not been able to get a thread tap to cut the thread.

Get a pin and put it in one of the holes and bottom it out and mark the pin (this will be you new depth for your new holes later)

use this product and fill the holes completely.

http://www.loctiteproducts.com/p/epxy_p ... Bonder.htm

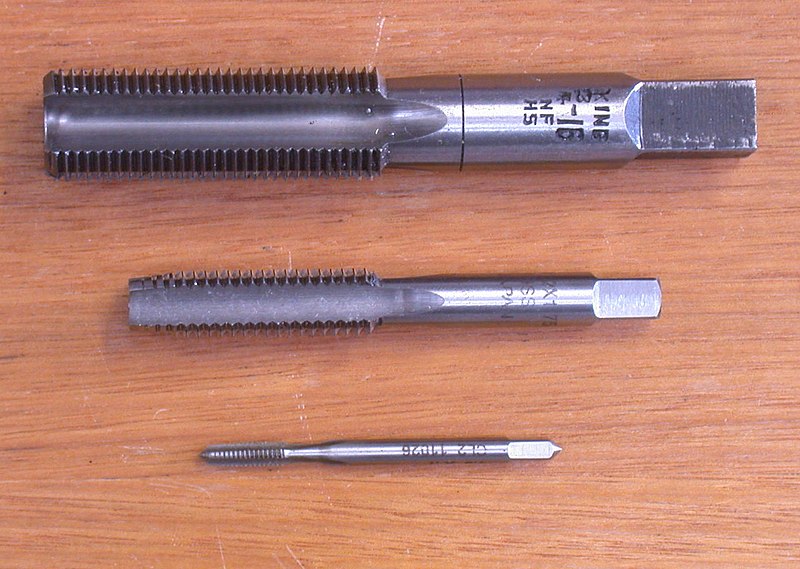

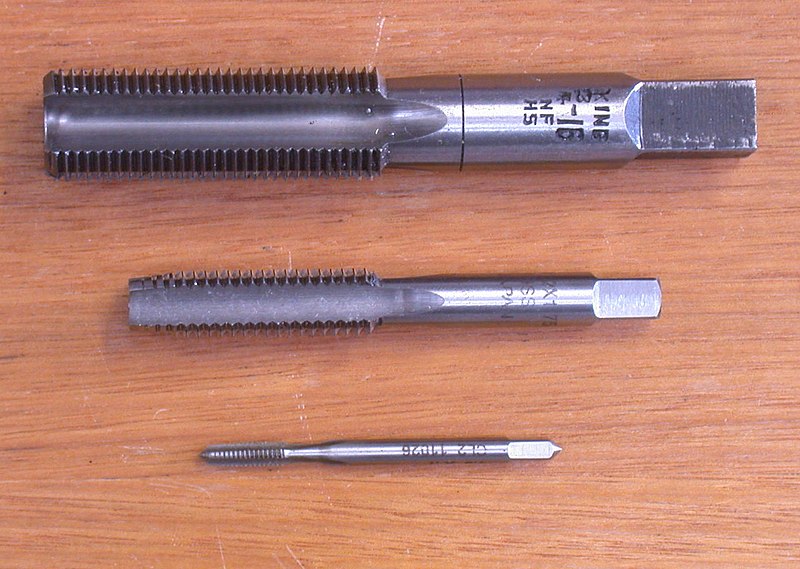

and then get one of your existing screws and file the screw in 2 places (180 degrees apart) so that it looks like a tap (thread tap) ..... like this ....

So you get two grooves like above using a dremell and small cutting bit (so you are accurate with it). then place the top cover on and with a fine texter (marker) hold the cover and make sure it is centrallised in its locating groove.

one you have marked the 6 holes .... remove the top cover again and the use your pin marked above... and make a corresponding mark on your drill (do not drill this below the mark you have made) a 1.5mm drill and drill the 6 new holes (don't drill deeper than your mark).

Place your top housing back into its groove and use the screw tunnel as a guide toe keep the screw straight and located. (make sure you hold both covers tightly together to keep it all in place.

PUT A FEW DROPS OF LIGHT GRADE MACHINE OIL sae5 WILL DO ... on the screw threads to reduce friction when cutting the thread .... never put it on dry!

using your new home made ....thread cutting screw..... turn the slot cut screw in 1 and a 1/2 to 2 turns (clockwise) then back it off 1/2 a turn ..... Make sure you are no going down on a angle and are plumb and square..... repeat ....1 and a 1/2 to 2 turns (clockwise) then back it off 1/2 a turn. Remove the screw and then blow out the cuttings in the bottom of the hole.

Keep doing this until your screw is seated on the bottom of the tunnel face (bottomed out and tight again).

Repeat this for all 6 screws....

Special Note:

1. Don't forget to keep removing the screw and clearing out the tailings (plastic Swarf) or you will split the threaded tower.

2. Keep good pressure on the screw when cutting the thread as you do NOT want to just sit it on and keep spinning it or your will just drill it out with your new cutting tool.

3. Once you have one screw in .... remove the cutting tool and then screw in one of the other screws.....

Now you can move onto the next and the next ..... and you will be done!

I have done this type of repair on almost every material all over the world ..... I have been a Diesel Engineer and Fuel Injection and Turbo Engineer for over 15 years (none practicing now) and this is one of my super gem secrets when the chips are down in a third world country and you can not get the correct tooling. I would do it with grade 7 bolts etc to cut and repair threads out in the field.... whether a mine, fuel room or my workshop.... it really works!

WARNING ... This will take some time and patience.....

I have used this method with both metal (using either alloy plastic metal or cast metal plastic) and plastic in automotive and earthmoving equipment when I have not been able to get a thread tap to cut the thread.

Get a pin and put it in one of the holes and bottom it out and mark the pin (this will be you new depth for your new holes later)

use this product and fill the holes completely.

http://www.loctiteproducts.com/p/epxy_p ... Bonder.htm

and then get one of your existing screws and file the screw in 2 places (180 degrees apart) so that it looks like a tap (thread tap) ..... like this ....

So you get two grooves like above using a dremell and small cutting bit (so you are accurate with it). then place the top cover on and with a fine texter (marker) hold the cover and make sure it is centrallised in its locating groove.

one you have marked the 6 holes .... remove the top cover again and the use your pin marked above... and make a corresponding mark on your drill (do not drill this below the mark you have made) a 1.5mm drill and drill the 6 new holes (don't drill deeper than your mark).

Place your top housing back into its groove and use the screw tunnel as a guide toe keep the screw straight and located. (make sure you hold both covers tightly together to keep it all in place.

PUT A FEW DROPS OF LIGHT GRADE MACHINE OIL sae5 WILL DO ... on the screw threads to reduce friction when cutting the thread .... never put it on dry!

using your new home made ....thread cutting screw..... turn the slot cut screw in 1 and a 1/2 to 2 turns (clockwise) then back it off 1/2 a turn ..... Make sure you are no going down on a angle and are plumb and square..... repeat ....1 and a 1/2 to 2 turns (clockwise) then back it off 1/2 a turn. Remove the screw and then blow out the cuttings in the bottom of the hole.

Keep doing this until your screw is seated on the bottom of the tunnel face (bottomed out and tight again).

Repeat this for all 6 screws....

Special Note:

1. Don't forget to keep removing the screw and clearing out the tailings (plastic Swarf) or you will split the threaded tower.

2. Keep good pressure on the screw when cutting the thread as you do NOT want to just sit it on and keep spinning it or your will just drill it out with your new cutting tool.

3. Once you have one screw in .... remove the cutting tool and then screw in one of the other screws.....

Now you can move onto the next and the next ..... and you will be done!

I have done this type of repair on almost every material all over the world ..... I have been a Diesel Engineer and Fuel Injection and Turbo Engineer for over 15 years (none practicing now) and this is one of my super gem secrets when the chips are down in a third world country and you can not get the correct tooling. I would do it with grade 7 bolts etc to cut and repair threads out in the field.... whether a mine, fuel room or my workshop.... it really works!

Re: Repairing stripped Tx case screws?

After many years in the electronic service industry, the easiest way to fix striped threads on posts or split posts.

Is to use a piece of suitable sized heat shrink over the post, and if you want to make it a permanent job(as in the 9X's case where back removal will be done numerous times) fill with epoxy and when set use appropriate drill size 1/16 eg and use original screws.

Is to use a piece of suitable sized heat shrink over the post, and if you want to make it a permanent job(as in the 9X's case where back removal will be done numerous times) fill with epoxy and when set use appropriate drill size 1/16 eg and use original screws.

- Rob Thomson

- Site Admin

- Posts: 4543

- Joined: Tue Dec 27, 2011 11:34 am

- Country: United Kingdom

- Location: Albury, Guildford

- Contact:

Re: Repairing stripped Tx case screws?

Sadly.. the posts in the 9x case are only 'half' accessible.. so the heat shrink does not work - but epoxy fill should!

Slope Soaring, FPV, and pretty much anything 'high tech'

...........if you think it should be in the wiki.. ask me for wiki access, then go add it!

...........if you think it should be in the wiki.. ask me for wiki access, then go add it!

Re: Repairing stripped Tx case screws?

Even the half ones can be cut between post and case enough to get a decent piece of heatshrink on, to keep in epoxy also.

Forgot to mention, use tip of soldering iron to effect the shrinking bit.

Forgot to mention, use tip of soldering iron to effect the shrinking bit.

Re: Repairing stripped Tx case screws?

Well, I don't have the issue yet, but what about to fix permanently a long enough M3 threaded axle inside posts ?

Then just use a washer and a nylstop nut on the back case. They would be apparent on the back but I don't think that's annoying.

Also, 4 screws to attach the 9x cases together are enough IMO, 2 top and 2 bottom.

Alternatively, drill out completely the stripped posts on the front case, then use bolts.

Nuts would be apparent on front case.

There are some nice thin M3 nuts in case the relief is annoying. Nuts can also be heated with a strong soldering iron so they can be pushed a bit inside the case by melting it. Well, not sure about that, it depends on case thickness and its ability to melt nicely

Then just use a washer and a nylstop nut on the back case. They would be apparent on the back but I don't think that's annoying.

Also, 4 screws to attach the 9x cases together are enough IMO, 2 top and 2 bottom.

Alternatively, drill out completely the stripped posts on the front case, then use bolts.

Nuts would be apparent on front case.

There are some nice thin M3 nuts in case the relief is annoying. Nuts can also be heated with a strong soldering iron so they can be pushed a bit inside the case by melting it. Well, not sure about that, it depends on case thickness and its ability to melt nicely